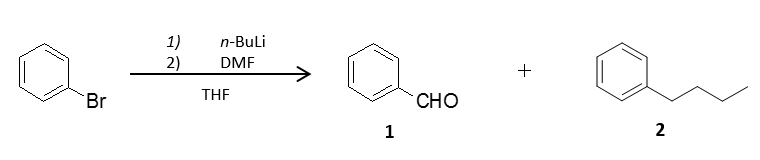

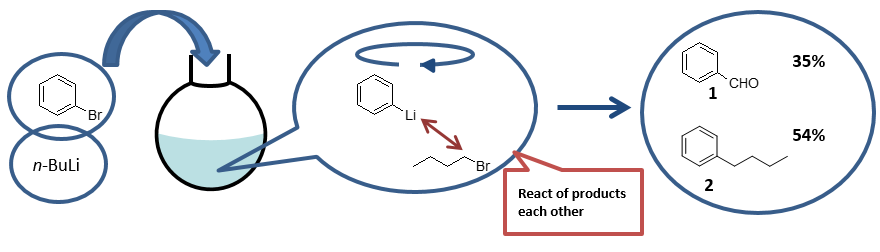

In a conventional batch system (flask), synthesizing of a target compound (No.1 above) alone has been extremely difficult when a product is highly reactive. This is because undesired production of a non-target compound (No. 2 above) due to further reaction of the product takes place even at low temperature.

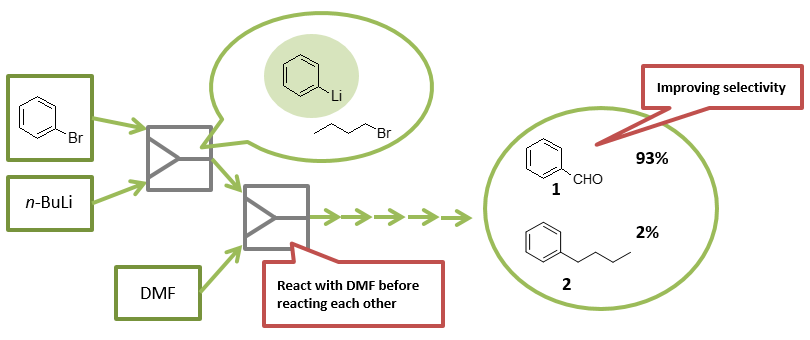

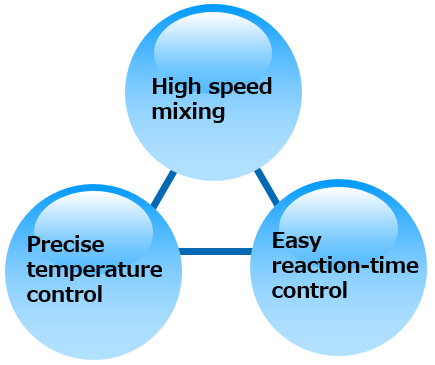

In a flow micro reaction system, residence time of a highly reactive compound can be kept short just by adjusting the flow rate, and a rapid reaction with DMF by micromixing minimizes the undesired production of byproducts. Since there is no need to keep the temperature low, less energy cost is required.